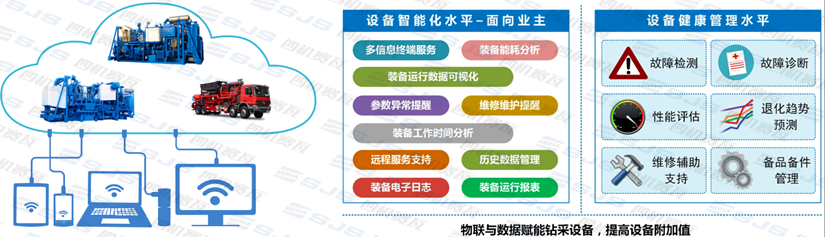

Leading in automation and information technology, SJS provides customers with intelligent solutions. The SOFElink is a data platform for oil and gas equipment, running on websites and APPs. It is designed for data acquisition and big data mining with IoT technology for equipment lifecycle management. SOFElink is used to access all cementing and fracturing equipment, including auxiliary devices such as alternators. Use IoT cloud service for wireless centralized control for the equipment equipped with SOFEview data acquisition software.

Features

Equipment positioning | For positioning of equipment, over-limit alarm by setting Geo fence. | Operation report | Operation report by week, month, quarter and year, including operation rate, service hours, running conditions, failure rate, fuel consumption and maintenance. |

Fuel consumption monitoring | Monitoring of daily fuel consumption, average fuel consumption and abnormal fuel consumption alarms. | In-depth maintenance and care | To work out reasonable maintenance plans and provide accurate maintenance reminders and records according to user-defined parameters |

Equipment parameters | Real-time logging of key parameters of the equipment, including: on-line time, cumulative running time, utilization rate, load rate, engine speed, transmission gear, discharge pressure, pump displacement, alarm, oil pressure, oil temperature, etc. | Spare Parts | Input of spare parts information, wearing parts information and corresponding material codes to provide more accurate information services of inventory and purchase cycle. |

Real-time curve | To display the operation trend and dynamics of the equipment grouped by timestamp. | Equipment performance log | To generate logs of equipment startup, shutdown, alarm, maintenance and overhaul. |

Fault alarm | Fault alarms of engines, transmissions and pumps. | intelligent analysis | Analysis of the operation status and working conditions of the equipment, such as working pressure range, discharge pressure range, etc. by collecting big data. |

Historical data | View of history data at any time and save of all data of the equipment after leaving the factory for fault analysis. | Key component diagnosis | Providing the diagnosis and anomaly detection of core components such as plunger pumps and output the health status of the equipment in its operating environment. |

Public number

Public number