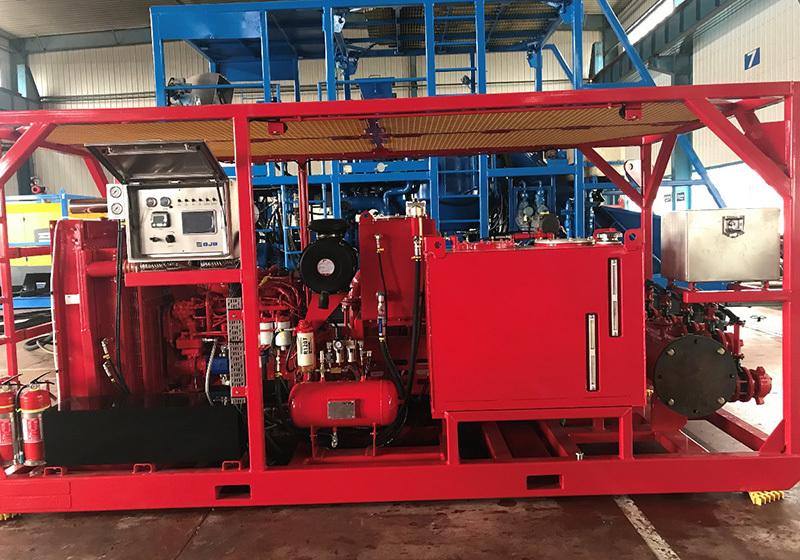

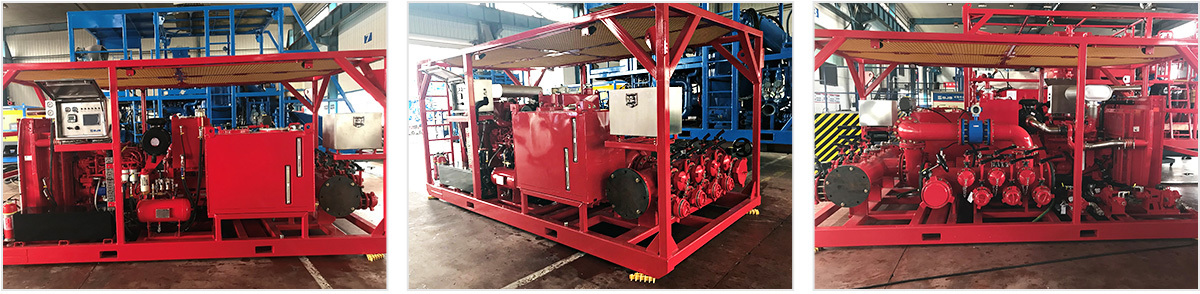

PLS-75 Fluid Pumper Skid

|

Description |

Model/Size/Specs |

|

Control Mode |

Auto Control |

|

Skid Construction |

Integrately Welded, c/w Crash Frame, Lifting Points on the top and Forklift Slots on the bottom. |

|

Engine |

CUMMINS Engine,QSL8.9-C325 |

|

Clutch |

WPT SP311 Pneumatic Clutch |

|

Centrifugal Pump |

Acid-Resistant,SERVA SCP10x8x14 |

|

Liquid Additive Pump |

Cam Pump, 3 sets |

|

Drive Shaft |

Universal-joint Drive Shaft |

|

Fuel Tank |

600 L |

|

Hydraulic Tank |

200 L |

|

Manifold System |

Carbon Steel lined with Flouroplastics |

|

Max Discharge Pressure |

0.45 MPa (65 psi) |

|

Max Discharge Rate |

12 m³/min (75 bbl/min) |

|

Working Medium |

Clean Water or Liquid Additive |

|

Power Supply |

24 VDC |

|

Working Temperature Range |

-20℃ ― +50℃ |

|

Interfaces |

Suction Port: 8" Connection (1); 4" FIG.206 Female Union (8) |

|

Discharge Port: 8" Connection (1); 4" FIG.206 Female Union (6) |

|

|

Liquid Additive Suction Port: 1 1/2” & 2" Quick Connections |

|

|

Overall Dimensions (L x W x H) |

4,750 x 2,300 x 2,300 mm |

|

Weight Dry |

6,000 kg |

Features

- High reliability — PTFE lined manifold and acid resistant butterfly valve;

- Wide application — Designed to be widely used for acidizing and fracturing operations;

- Ease of operation — Designed to achieve centralized operation and monitoring. Warning symbols are set in hazardous areas;

- Adjustable displacement — To adjust the displacement by turning the engine throttle switch.

PLS-75 Fluid Pumper Skid

SJS Ltd.

Address: 101# West Ring Road, Jingzhou City, Hubei Province, China#

Telephone:+86-716-8012162

Fax: +86-0716-8429433

E-mail:info@sjs.ServaCorp.com

Public number

Public number